- [未审核]涡轮增压系统清洗套装

-

针对性涡轮配方,超强油泥清除能力。高活性分子,快速溶解,不残留,易溶于水,不易挥发,无刺激性气味,无腐蚀性。清洗车辆涡轮增压系统(涡轮增压器和涡轮增压路径),保持涡轮系统最佳工作状态,增加涡轮增压器使用寿命。

优道智能涡轮增压清洗项目:

由优道与华南理工大学化学系,采用美国专项技术联合开发,是国内首创智能涡轮增压系统清洗项目,荣获得国家2项发明专利。

施工工艺专利号:201810154620.9

产 品 专 利 号:201810173520.0

品牌:UD优道

系统:进排气系统

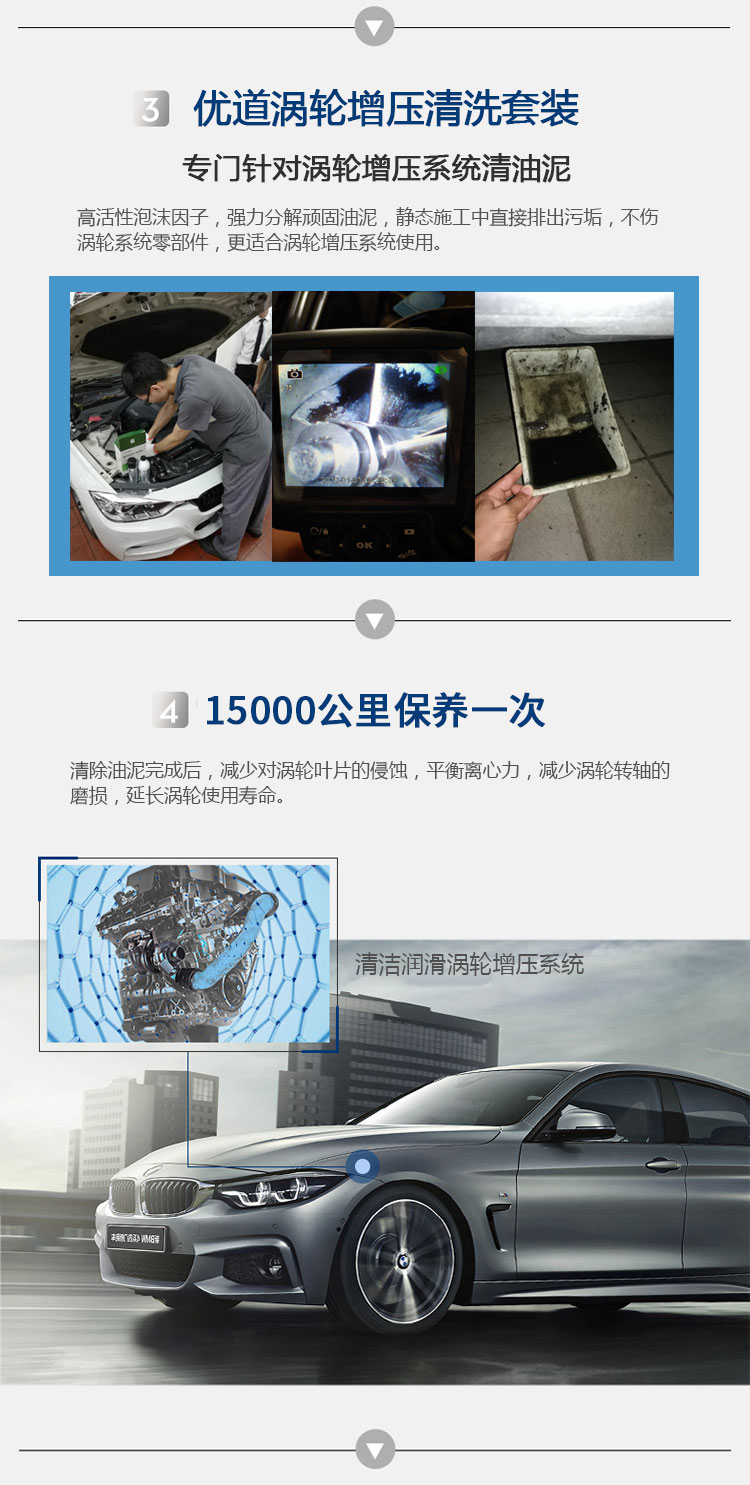

涡轮增压系统清洗套装

产品编号:UD-02.271/325ML UD-02.273/500ML

企业标准:Q/YKJH 4

仅供4S店使用

产品特点:

1.涡轮油泥清除剂

产品说明:

1、适用于免拆清洁各类型内燃机的涡轮增压系统,泡沫浓厚,清洁油泥积碳能力强,可有效清除涡轮增压进气道、进气端涡轮叶片,进气冷却器内的油泥积碳沉积物,优化进气量,减流阻,提升增压器效率。

2、恢复增压器性能,保持最佳工作状态,提高经济性,节省燃油,降低排放。

3、对氧传感器以及三元催化无害。建议每10000公里使用一次。非专业维修人员请勿自己操作。

2. 涡轮冲洗液

产品说明:

1、适用于免拆清洁各类型内燃机的涡轮增压系统,泡沫浓厚,清洁油泥积碳能力强,可有效清除涡轮增压进气道、进气端涡轮叶片,进气冷却器内的油泥积碳沉积物,优化进气量,减少流阻,提升增压器效率。

2、恢复增压器性能,保持最佳工作状态,提高经济性,节省燃油,降低排放。

3、对氧传感器以及三元催化无害。建议每10000公里使用一次。非专业维修人员请勿自己操作。

套装使用说明:

1、将涡轮油泥清除剂注入增压系统内;

2、导入涡轮冲洗液,使用专业设备进行冲洗;

3、启动车辆进行排碳;

4、施工完成。

Product features:

1. Turbine sludge scavenger

Product description:

1, apply to avoid cleaning of various types of internal combustion engine turbocharging system, foam, clean oil sludge carbon ability strong, can effectively remove the turbo inlet, turbine blade inlet end, inlet oil sludge carbon sediment in the cooler, optimize the air inflow, reduction of flow resistance, promote efficiency of the supercharger.

2. Restore the performance of the supercharger, keep the best working condition, improve economy, save fuel and reduce emissions.

3. Harmless to oxygen sensor and ternary catalysis. It is recommended to be used every 10,000 kilometers. Non-professional maintenance personnel should not operate by themselves.

2. Turbine washing liquid

Product description:

1, apply to avoid cleaning of various types of internal combustion engine turbocharging system, foam, clean oil sludge carbon ability strong, can effectively remove the turbo inlet, turbine blade inlet end, inlet oil sludge carbon sediment in the cooler, optimize the volume, reduce the flow resistance, promote efficiency of the supercharger.

2. Restore the performance of the supercharger, keep the best working condition, improve economy, save fuel and reduce emissions.

3. Harmless to oxygen sensor and ternary catalysis. It is recommended to be used every 10,000 kilometers. Non-professional maintenance personnel should not operate by themselves.

Usege:

1. Inject the turbo sludge remover into the pressurizing system;

2. Introduce turbine washing liquid and use professional equipment for washing;

3. Start the vehicle for carbon emission;

4. Completion of construction.

![[未审核]涡轮增压系统清洗套装 [未审核]涡轮增压系统清洗套装](/upLoad/product/180423/201804231748407071.jpg)

![[未审核]涡轮增压系统清洗套装 [未审核]涡轮增压系统清洗套装](/upLoad/product/180423/201804231748398310.jpg)

![[未审核]涡轮增压系统清洗套装 [未审核]涡轮增压系统清洗套装](/upLoad/product/180423/201804231748404549.jpg)